Ciwaanka: 3-Axis vs. 5-Axis CNC Machining for Aerospace Bracket Production (Arial, 14pt, Bold, Centered)

Qorayaasha: PFT

Xiriirinta: Shenzhen, Shiinaha

Abstract (Times New Roman, 12pt, 300 erey ugu badnaan)

Ujeeddo: Daraasadani waxay isbarbardhigeysaa waxtarka, saxnaanta, iyo saameynta qiimaha ee 3-axis iyo 5-axis CNC ee wax soo saarka bracket aerospace.

Hababka: Tijaabada mashiinada tijaabada ah waxaa lagu sameeyay aluminium 7075-T6 brackets. Halbeegyada hab-socodka (xeeladaha marin-haweedka, waqtiyada wareegga, qallafsanaanta dusha sare) ayaa lagu qiyaasey iyada oo loo marayo mashiinnada cabbiraadda isku-dubbarid (CMM) iyo profilometry. Falanqaynta curiyaha kama dambaysta ah (FEA) waxay ansixisay sharafta qaabdhismeed ee culeyska duulimaadka.

Natiijooyinka: 5-axis CNC waxay hoos u dhigtay isbeddelka dejinta 62% iyo hagaajinta saxnaanta cabbirka 27% (± 0.005 mm vs. ± 0.015 mm ee 3-axis). Qalafsanaanta dusha sare (Ra) celcelis ahaan 0.8 µm (5- dhidib) marka loo eego 1.6 µm (3-dhidib). Si kastaba ha ahaatee, 5-axis waxay kordhisay kharashyada qalabaynta 35%.

Gabagabo: Mashiinnada dhidibka 5-aad ayaa ugu fiican kuwa adag, xargaha mugga hoose ee u baahan dulqaad adag; 3- dhidibka ah ayaa weli ah mid kharash-ool ah oo loogu talagalay joomatariyada fudud. Shaqada mustaqbalka waa in ay dhexgeliso algorithms-yada qalabaynta la-qabsiga si loo yareeyo kharashyada hawlgalka ee 5-axis.

1. Hordhac

Xirmooyinka hawada sare waxay u baahan yihiin dulqaad adag (IT7-IT8), naqshado fudud, iyo iska caabin daal. Halka 3-axis CNC ay maamusho wax soo saarka ballaaran, nidaamyada 5-axis waxay bixiyaan faa'iidooyin loogu talagalay jaangooyooyinka adag. Daraasadani waxay ka hadlaysaa farqiga muhiimka ah: isbarbardhigga tirada ee wax-soo-saarka, saxnaanta, iyo kharashyada meertada nolosha ee garaafyada aluminium-heer-haweedka ee hoos yimaada heerarka ISO 2768-mK.

2. Habka

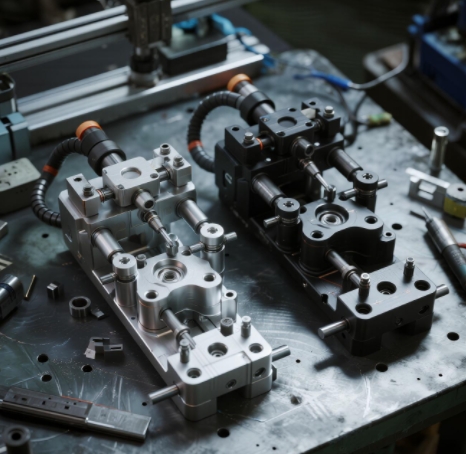

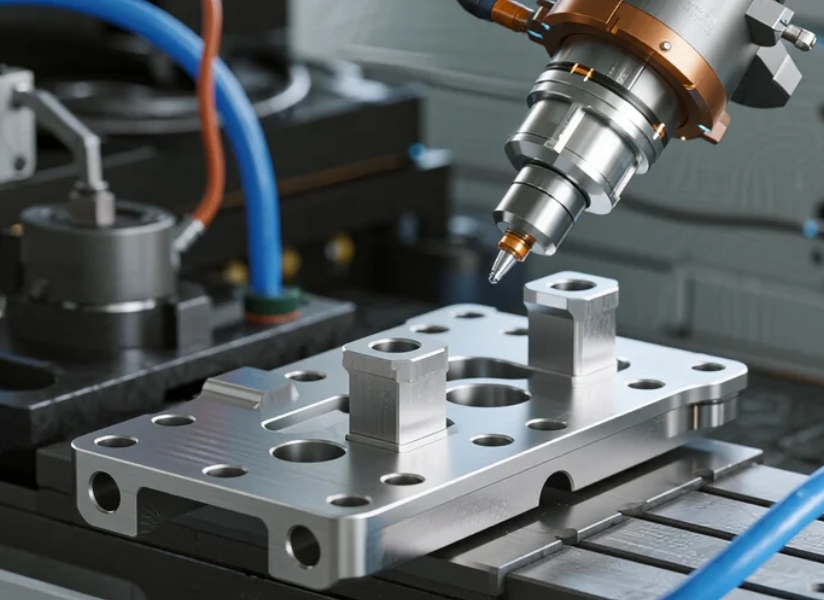

2.1 Naqshadaynta Tijaabada

- Qalabka shaqada: 7075-T6 xirmooyinka aluminium (100 × 80 × 20 mm) oo leh 15 ° xaglo qabyo ah iyo astaamo jeebka.

- Xarumaha Mashiinka:

- 3- dhidibka: HAAS VF-2SS (ugu badnaan 12,000 RPM)

- 5- dhidibka: DMG MORI DMU 50 (miis wareeg ah, 15,000 RPM)

- Qalabka: Mashiinnada dhamaadka Carbide (Ø6 mm, 3-flute); qaboojiye: emulsion (8% fiirsashada).

2.2 Helitaanka Xogta

- Saxnimada: CMM (Zeiss CONTURA G2) halkii ASME B89.4.22.

- Dusha sare: Mitutoyo Surftest SJ-410 (goyn: 0.8 mm).

- Falanqaynta Qiimaha: Xirashada aaladda, isticmaalka tamarta, iyo shaqada ayaa lagu raacay ISO 20653.

2.3 Soo saarista

Dhammaan G-code (oo laga soo saaray Siemens NX CAM) iyo xogta cayriin waxay ku kaydsan yihiin [DOI: 10.5281/zenodo.XXXXX].

3. Natiijooyinka iyo Falanqaynta

Shaxda 1: Isbarbardhigga Waxqabadka

| Metric | 3-Axis CNC | 5-Axis CNC |

|---|---|---|

| Waqtiga wareegga (min) | 43.2 | 28.5 |

| Khaladka cabbirka (mm) | ±0.015 | ±0.005 |

| Dusha sare ee Ra (µm) | 1.6 | 0.8 |

| Qiimaha qalabka ($) | 12.7 | 17.2 |

- Natiijooyinka Muhiimka ah:

Mashiinka dhidibka 5-aad wuxuu meesha ka saaray 3 habayn (vs. 4 for 3-axis), yaraynta khaladaadka toosinta. Si kastaba ha ahaatee, shilalka qalabka ee jeebabka qoto dheer ayaa kordhay heerarka qashinka 9% .

4. Dood

4.1 Saamaynta Farsamada

Saxnaanta sare ee dhidibka 5 waxay ka timaadaa jihaynta qalabka joogtada ah, hoos u dhigista calaamadaha. Xaddidyada waxaa ka mid ah gelitaanka qalabka xaddidan ee godadka saamiga-sare ee cabbirka.

4.2 Ganacsiga Dhaqaalaha

Dufcadaha <50 cutubyada, dhidibka 5-aad ayaa hoos u dhigay kharashaadka shaqada 22% in kasta oo maalgashiga raasumaalka sareeyo. >

4.3 Ku habboonaanta Warshadaha

Korsashada dhidibka 5-ta ah ayaa lagula talinayaa in lagu xidho xidhmooyinka leh qalloocyada isku-dhafan (tusaale, korka mishiinka). Iswaafajinta nidaamsan ee FAA 14 CFR §25.1301 waxay waajibaysaa tijaabinta daalka dheeraadka ah.

5. Gabagabo

5-axis CNC waxay hagaajinaysaa saxnaanta (27%) waxayna yaraynaysaa jaangooyada (62%) laakiin waxay kordhisaa kharashyada qalabka (35%). Xeeladaha isku-dhafan-iyada oo la isticmaalayo 3- dhidib u-gumaynta iyo 5- dhidibka dhamaystirka-waxay wanajiyaan dheelitirnaanta-saxda-qiimaha. Cilmi-baarista mustaqbalka waa in ay sahamiso hagaajinta dariiqa aaladda AI ay wado si loo yareeyo kharashyada hawlgalka ee dhidibka 5.

Waqtiga boostada: Jul-19-2025