Magnetic vs Pneumatic Workholding ee Aluminiumka xaashida khafiifka ah

Qore: PFT, Shenzhen

Abstract

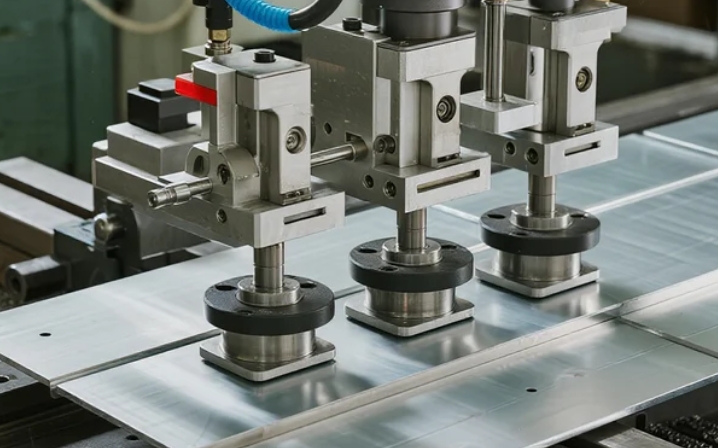

Mashiinka saxda ah ee xaashida aluminiumka khafiifka ah (<3mm) waxay wajaheysaa caqabado shaqo oo muhiim ah. Daraasadani waxay isbarbar dhigaysaa nidaamyada isku xidhka magnetic iyo pneumatic ee hoos yimaada xaaladaha wax-shiidka ee CNC. Qiyaasaha tijaabinta waxaa ka mid ah joogteynta xoogga, xasilloonida kulaylka (20°C–80°C), qoyaanka gariirka, iyo qalloocinta dusha sare. Xirmooyinka vacuum pneumatic waxay ilaaliyeen fidsanaanta 0.02mm ee go'yaal 0.8mm ah laakiin waxay u baahdeen sagxadaha daboolka oo qumman. Xididdada korantada ayaa awood u siisay gelitaanka dhidibka 5-aad iyo hoos u dhigidda waqtiga 60%, weli qulqulka qulqulka qulqulka ayaa sababay kulayl gudaha ah oo ka badan 45°C at 15,000 RPM. Natiijooyinku waxay muujinayaan nidaamyada faakuumka inay hagaajiyaan dhammaystirka dusha sare ee go'yaal> 0.5mm, halka xalalka magnetic ay hagaajinayaan dabacsanaanta soo saarista degdegga ah. Xaddidyada waxaa ka mid ah hababka isku-dhafan ee aan la tijaabin iyo beddelka ku-saleysan koollada.

1 Hordhac

Waraaqaha aluminiumka khafiifka ah ee warshadaha tamarta laga bilaabo hawada hawada (maqaarka fiyuuska) ilaa qalabka elektiroonigga ah (samaynta kuleylka kuleylka). Hase yeeshe sahannada warshadaha 2025 waxay muujinayaan 42% cilladaha saxda ah waxay ka yimaadaan dhaqdhaqaaqa shaqada inta lagu jiro mashiinka. Xakamaynta farsamada caadiga ah waxay badiyaa qalloociyaan xaashiyada-1mm-hoosaadka, halka hababka ku salaysan cajaladuhu aanay lahayn adag. Daraasadani waxay qiyaasaysaa laba xalal horumarsan: chucks electromagnetic leveraging remanence technology technology iyo pneumatic systems with multi-zone vacuum control.

2 Habka

2.1 Naqshadaynta Tijaabada

-

Qalabka: 6061-T6 aluminium go'yaal (0.5mm/0.8mm/1.2mm)

-

Qalabka:

-

MagnetikGROB 4- dhidibka elektromagnetic-ka (xoogga goobta 0.8T)

-

Pneumatic: SCHUNK saxan faaruq ah oo leh 36-aag badan

-

-

Tijaabada: Fikirka dusha sare (laser interferometer), sawirka kulaylka (FLIR T540), falanqaynta gariir (3-axis accelerometers)

2.2 Tijaabada Hab-maamuuska

-

Xasilooni Joogta ah: Cabbir leexashada xoogga dhinaca 5N

-

Baaskiilka kulaylka: Heerkulka diiwaan gashan inta lagu jiro mishiinka qashinka (Ø6mm warshad dhamaadka, 12,000 RPM)

-

Qalalaasaha Firfircoon: Ku qiyaas baaxadda gariirka inta jeer ee soo noqnoqda (500-3000 Hz)

3 Natiijooyinka iyo Falanqaynta

3.1 Waxqabadka xajinta

| Halbeegga | Pneumatic (0.8mm) | Magnetik (0.8mm) |

|---|---|---|

| Celcelis Qallooc | 0.02mm | 0.15mm |

| Waqtiga Dejinta | 8.5 daq | 3.2 daq |

| Heerkulka ugu sarreeya | 22°C | 48°C |

Jaantuska 1: Nidaamyada faakuumka waxa la ilaaliyay <5μm kala duwanaanshiyaha dusha sare inta lagu jiro shiididda wejiga, halka xajinta birlabku ay muujisay wiish 0.12mm gees ah balaarinta kulaylka awgeed.

3.2 Tilmaamaha Gariirka

Pneumatic chucks waxay hoos u dhigtay isku-dhafka 15dB at 2,200Hz - oo muhiim u ah hawlgallada dhamaystirka ganaaxa. Haysashada magnetic waxay muujisay 40% baaxad weyn marka loo eego inta jeer ee hawlgelinta qalabka.

4 Dood

4.1 Tignoolajiyada Ganacsiga

-

Faa'iidada Pneumatic: Deganaanshaha kulaylka sareeyo iyo qoynta gariirka waxay ku habboon yihiin codsiyada dulqaadka sare leh sida saldhigyada qaybaha indhaha.

-

Edge Magnetic: Dib-u-habaynta degdega ah waxay taageertaa jawiga dukaanka shaqada ee maaraynta cabbirrada dufcadaha kala duwan.

Xaddidaad: Tijaabooyin laga saaray go'yaal dalool ama saliid leh halkaas oo waxtarka faakuumku hoos u dhaco>70%. Xalalka isku-dhafka ah waxay dammaanad qaadayaan daraasad mustaqbalka.

5 Gabagabo

Makiinadaha xaashida khafiifka ah ee aluminium:

-

Qabashada shaqada pneumatic waxay keentaa saxnaanta sare ee dhumucda>0.5mm oo leh sagxadaha aan jabnayn

-

Nidaamyada magnetic waxay yareeyaan wakhtiga aan goynin 60% laakiin waxay u baahan yihiin xeelado qaboojiye ah oo lagu maareeyo kulaylka

-

Xulashada ugu fiican waxay ku xiran tahay baahida wax soo saarka iyo shuruudaha dulqaadka

Cilmi-baadhista mustaqbalka waa inay sahamisaa isku-xidhka isku-dhafan ee la-qabsiga ah iyo naqshadaha korantada ee faragelinta hooseeya.

Waqtiga boostada: Jul-24-2025